BTG Biomass Technology Group

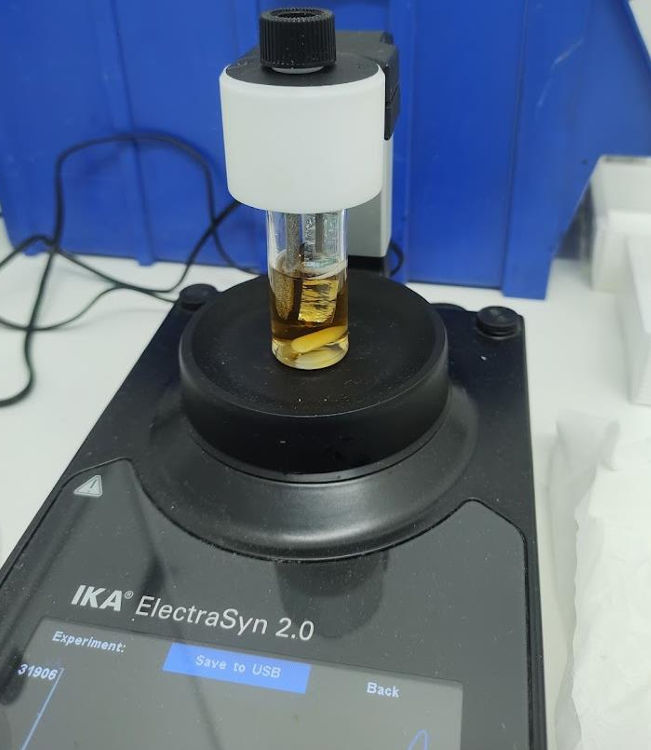

In this internship, the upgrading of pyrolytic lignin (a fraction of pyrolysis oil) through electrooxidation was studied in an IKA ElectraSyn 2.0 equipment with nickel foam and Boron Doped Diamond (BDD) electrodes in an undivided cell and in an alkaline medium with Rapid Alternating Pulses (rAP). GPC, pH, carbon residue (CR), elemental analysis (EA), and HPLC analysis were used to check molecular weight and composition changes of pyrolytic lignin, BDD being the electrode with which we obtained the most significant changes, turning a dark brown solution into a light orange one. As rAP allows oxidation and reduction with the same electrode, pyrolysis oil (sugars and lignin) was also treated using both BDD electrodes with rAP. We obtained a light orange liquid with a white sandy powder at the bottom of the cell. The liquid fraction showed it still has heavy compounds, but they may be easier to upgrade in longer electrolysis.

This internship was executed at BTG – Biomass Technology Group in Enschede, and it was interesting to work with because it presents a novel way to use pyrolysis oil that can help us use biomass as a source of chemicals that usually come from petrol. The company has most of the equipment to execute analysis and experiments, but if something else is needed, they and their partners can help you. Furthermore, BTG people are always approachable so, whenever required, they can help you with your questions. Working in a company that combines research and industry in biomass is nice, making it unique and interesting for an internship.

The IKA ElectraSyn 2.0 equipment for electrolysis at BTG.

Comments

Log in to read and post comments