Demcon MIM 1

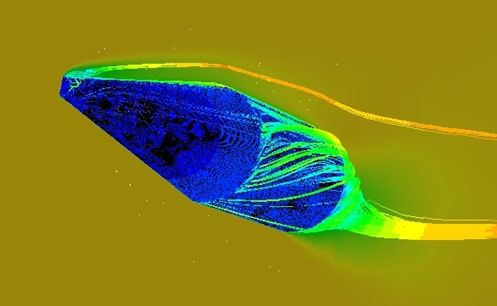

Metal injection moulding (MIM) is an innovative net-shape technology for series production of complex shaped metal parts. Only a small number of companies is specialized in this technique because of its complexity and many challenges to control it. Demcon MIM, located at Kennispark Twente, is one of them. The technology involves multiple steps, including moulding, debinding, and sintering. The internship involved conducting a series of tests to assess the effect of process parameters on material properties. This included for example density measurements, hardness tests, tensile tests, and microscopic testing. The company owns a metallurgic lab in which part of the tests could be performed. Tensile tests and SEM microscopy were performed at the UT. The first weeks of the internship were mainly focussed on getting to know the company, making a plan, and producing the test samples. The weeks after were mainly on doing different tests in the metallurgic lab, finishing production of samples and processing test results. I really liked the variety of being on the production floor, at the office, and in the lab. The internship is the ideal moment to get an idea of what it is like to apply your knowledge in a professional environment. Communicating with fellow colleagues, being engineers as well as operators, has been an important part of this learning process. The final two weeks were mainly dedicated to processing the test results and writing a report. The report discusses the test results, including a list of statements on the sensitivity of process parameters.

Comments

Log in to read and post comments