NTS Additive Manufacturing

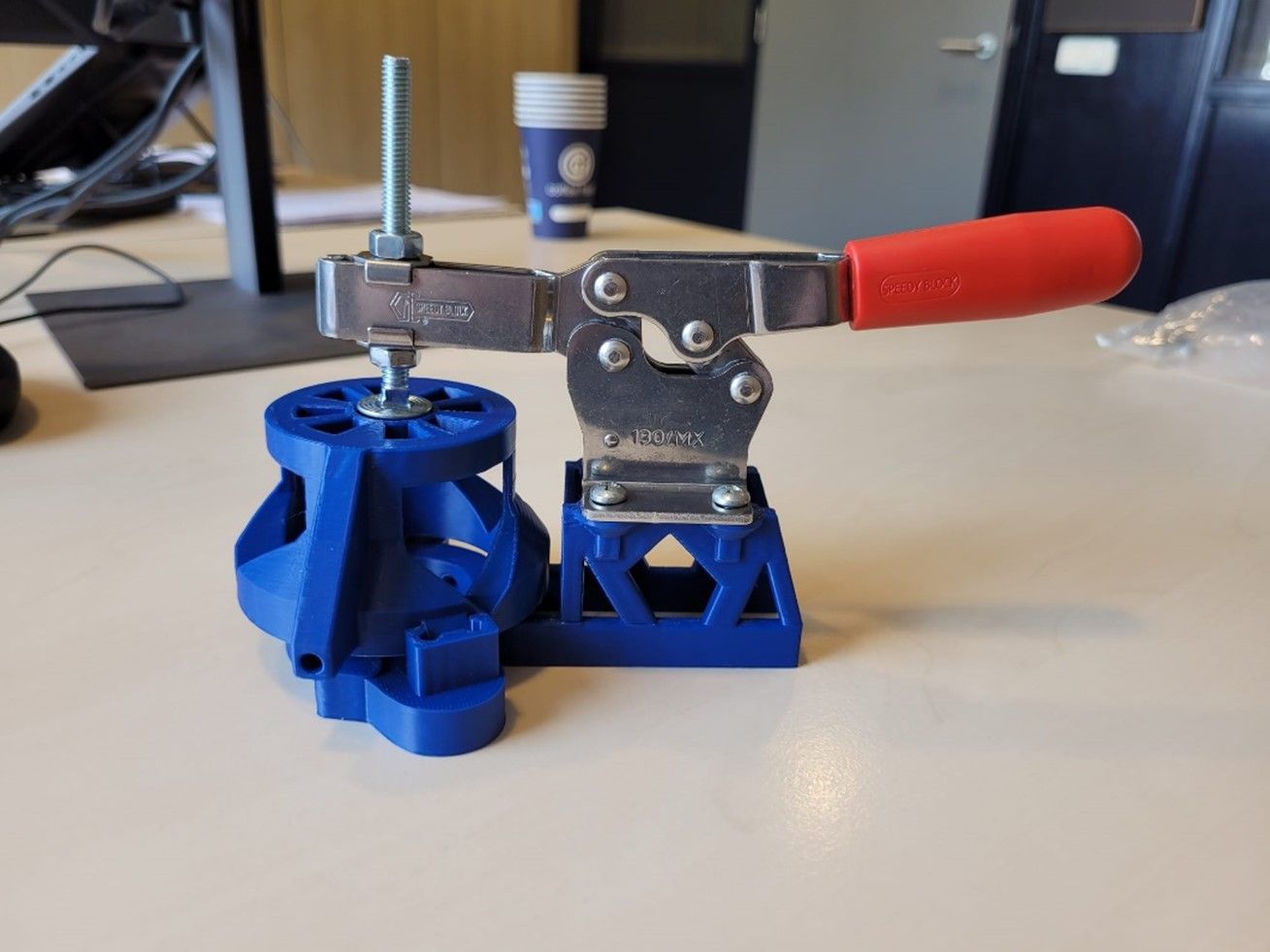

NTS Additive Manufacturing is a department of the overarching NTS Group. Here, the focus lies on producing high-precision parts using additive manufacturing. One of their products must be tested before being delivered to the customer. The products are currently mounted onto molds using bolts for these test setups. This way of clamping the products takes too long for the operator and is inconvenient since small bolts are used, which can get lost easily or break. Therefore, the internship assignment is to design a new testing tool for the setups, where the operator can clamp the products more quickly to the moulds and/or test more products simultaneously on the same mould. The internship started with a requirement and failure modes analysis, where after the concepts are listed, the best concepts are chosen, and finally, the final designs are created. One of the final designs is printed out of plastics to use as a prototype and to test whether it meets the requirements set at the beginning of the project. The prototype is shown in the picture. The clamping and loosening times of the products are compared to each other, where it could be concluded that the new series tool clamps the products faster than the current tool, and thus, the main objective of the new design is fulfilled.

Comments

Log in to read and post comments