Sensirion

Internship at Sensirion with R&D sensor packaging

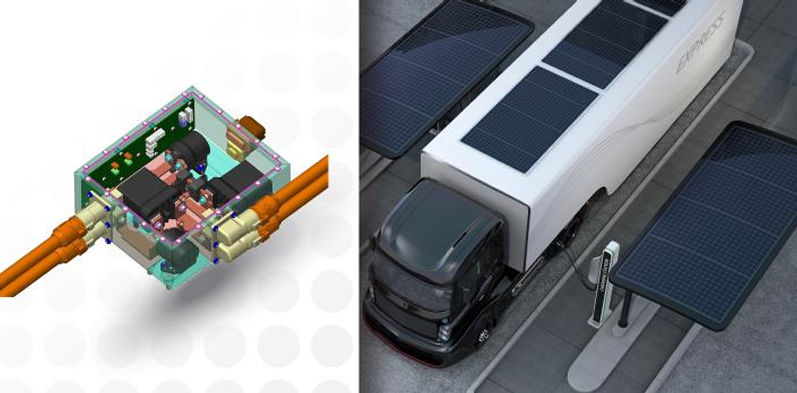

My 5.5-month internship at Sensirion was quite interesting and engaging. I was part of the R&D team for sensor packaging. Sensor packaging is everything that is built around the basic functional parts of the chip. Anything from the bonded wires to the used adhesives to the mould compound for the sensors is considered to be part of the packaging department’s responsibilities.

During the internship, I was mostly a gun-for-hire, helping out wherever I was needed. This made for a very diverse arrangement of tasks. Most experience was gained with the digital microscope, but I was introduced to a great part of the lab equipment. The digital microscope was mainly used for assessing the dimensions of the sensors and their features. This required some knowledge of coordinate systems general geometry and metrology. The X-ray machine was used to inspect the inside of the sensor. This could be for potential errors or damage, or for assessing component alignment. Two other machines that were used: the automatic dispenser for dispensing tiny droplets of chemical paste, and the shear testing machine for evaluating the adhesive connection between components and a substrate.

Next to lab work, another large part of the internship was data analysis. This mostly included working with Microsoft Excel to sort and analyse the exported data from the digital microscope. The microscope would export the data in a long list with feature names and their respective value. These values would then have to be copied, and sorted, and several statistical variables would have to be calculated from this data. In general, this work is quite straightforward. Therefore, the challenge lies in optimizing this process. To use Excel shortcuts and automate as much as possible, but still maintain the full flexibility of a manual process.

Sensirion also cares for its employees well. This is very noticeable in the amount of freedom that the employees have, but also the facilities that Sensirion offers. For instance, everyone is free to take a break whenever needed (outside of meetings and other mandatory events of course). Employees are allowed to access the free gym facility or play a game of ping pong etc. However, freedom was also present in choosing one’s tasks. Whenever someone has an idea on how to improve the working environment, (a custom tool or box organizers) it is usually allowed to pursue this improvement. Also, even though Switzerland is quite expensive, Sensirion’s interns are well compensated. If one can find affordable housing, money should not be a great issue.

Lastly, Switzerland itself is a great country to have visited. Not only do they have a public transport system that is extremely reliable, they also have beautiful mountain-and-lake sceneries to behold, enough lakes that one can swim in during the summer, and several interesting cities to visit. All-in-all, it is a wonderful experience.

Comments

Log in to read and post comments